Introduction to BSP Threads Chart

At Tube Aligen pro we provide most authentic information to our user to make there best experience. BSP Thread Chart threads are a globally recognized system for pipe connections, essential in industries like plumbing, oil and gas, and manufacturing. Developed from Joseph Whitworth’s pioneering 19th-century screw thread design, BSP threads are distinguished by their 55° flank angle and rounded crests and roots. This design enhances durability and leak resistance compared to the 60° NPT threads common in North America

Introduction British Standard Pipe (BSP)

British pipe thread chart (BSP) threads are a globally recognized threading system used in fluid and gas transfer applications. Originating in the UK, these threads are now integral to industries worldwide due to their reliability in creating leak-proof connections. BSP threads are categorized into two main types: parallel (BSPP) and tapered (BSPT), each adhering to specific ISO standards. Their applications span hydraulics, pneumatics, plumbing, and oil/gas systems, where precise BSP thread dimensions and compatibility are critical. Understanding BSP thread charts ensures proper component selection, reduces leakage risks, and enhances system longevity. This guide explores their standards, types, and real-world uses while addressing common challenges like BSP thread identification and BSP vs NPT threads.

BSP Thread Chart

| Thread Size | Major Diameter (in) | Major Diameter (mm) | Pitch (TPI) | Pitch (mm) | Taper |

|---|---|---|---|---|---|

| 1/8″ BSP | 0.383 | 9.728 | 28 | 0.907 | 1:16 |

| 1/4″ BSP | 0.518 | 13.157 | 19 | 1.337 | 1:16 |

| 3/8″ BSP | 0.656 | 16.662 | 19 | 1.337 | 1:16 |

| 1/2″ BSP | 0.825 | 20.955 | 14 | 1.814 | 1:16 |

| 3/4″ BSP | 1.041 | 26.441 | 14 | 1.814 | 1:16 |

| 7/8″ BSP | 1.189 | 30.201 | 11 | 2.309 | 1:16 |

| 1″ BSP | 1.309 | 33.249 | 11 | 2.309 | 1:16 |

| 1 1/8″ BSP | 1.466 | 37.236 | 11 | 2.309 | 1:16 |

| 1 1/4″ BSP | 1.650 | 41.910 | 11 | 2.309 | 1:16 |

| 1 3/8″ BSP | 1.811 | 45.999 | 11 | 2.309 | 1:16 |

| 1 1/2″ BSP | 1.925 | 48.895 | 11 | 2.309 | 1:16 |

| 1 3/4″ BSP | 2.083 | 52.908 | 11 | 2.309 | 1:16 |

| 2″ BSP | 2.250 | 57.150 | 11 | 2.309 | 1:16 |

| 2 1/4″ BSP | 2.417 | 61.392 | 11 | 2.309 | 1:16 |

| 2 1/2″ BSP | 2.583 | 65.608 | 11 | 2.309 | 1:16 |

| 2 3/4″ BSP | 2.750 | 69.850 | 11 | 2.309 | 1:16 |

| 3″ BSP | 2.917 | 74.092 | 11 | 2.309 | 1:16 |

| 3 1/4″ BSP | 3.083 | 78.300 | 11 | 2.309 | 1:16 |

| 3 1/2″ BSP | 3.249 | 82.524 | 11 | 2.309 | 1:16 |

| 3 3/4″ BSP | 3.415 | 86.741 | 11 | 2.309 | 1:16 |

| 4″ BSP | 3.581 | 90.957 | 11 | 2.309 | 1:16 |

| 4 1/2″ BSP | 3.913 | 99.390 | 11 | 2.309 | 1:16 |

| 5″ BSP | 4.245 | 107.823 | 11 | 2.309 | 1:16 |

| 5 1/2″ BSP | 4.577 | 116.256 | 11 | 2.309 | 1:16 |

| 6″ BSP | 4.909 | 124.689 | 11 | 2.309 | 1:16 |

Notes:

- BSPT = British Standard Pipe Taper

- BSPP = British Standard Pipe Parallel

- TPI = Threads Per Inch

BSP Thread Standards: ISO 228 (Parallel) and ISO 7 (Tapered)

BSP threads are governed by two ISO standards:

- ISO 228 (BSPP): Defines parallel threads where the diameter remains constant. These require a sealing washer or BSP thread sealant to prevent leaks, as the threads themselves don’t form a seal. Common in low-pressure hydraulic systems and water pipelines.

- ISO 7 (BSPT): Specifies tapered threads that narrow toward the end. The male thread compresses into the female fitting, creating a seal through deformation. Widely used in high-pressure gas and steam systems (BSP gas threads).

Both standards use a 55° thread angle, distinguishing them from NPT’s 60° angle. Proper adherence to these BSP thread standards ensures interoperability and safety across global industries.

BSP Thread Chart Breakdown:

Pitch, Diameter, and Thread Angle

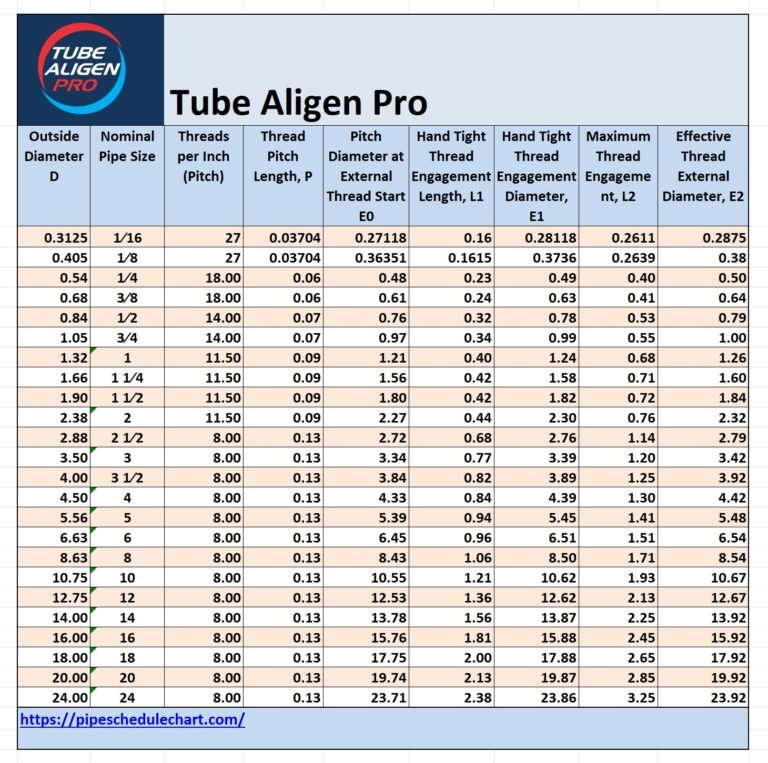

A BSP thread chart provides key dimensions for identifying and matching fittings:

- Major Diameter: The largest thread diameter (measured in inches or millimeters).

- Pitch: Distance between thread peaks (e.g., BSP thread pitch of 14 threads per inch for G1/2).

- Thread Angle: Always 55° for BSP.

Sample BSP Pipe Thread Chart Table

| Thread Size | Major Diameter (mm) | Pitch (TPI) | Type |

|---|---|---|---|

| G1/8 | 9.73 | 28 | Parallel |

| R1/2 | 20.99 | 14 | Tapered |

To read a chart, match measurements using a BSP thread gauge or caliper. For example, a fitting labeled “R3/4” refers to a tapered thread with a 26.44 mm major diameter.

Applications in Industrial and Plumbing Systems

- Hydraulics: BSPP threads are used in machinery due to their ability to withstand high pressures with proper sealing.

- Pneumatics: Air compressors often use BSPT for airtight connections in gas lines.

- Plumbing: BSPP dominates water supply systems, paired with sealant or washers.

- Oil/Gas: BSPT’s tapered design prevents leaks in volatile environments.

BSP vs Other Threads: NPT, Metric, and UNC

- NPT: Uses a 60° angle and tapered design. BSP vs NPT threads are incompatible without adapters due to differing pitches and angles.

- Metric: Measured in millimeters, but some BSP fitting sizes overlap (e.g., G1/2 ≈ 20 mm).

- UNC: Coarser pitch; rare in fluid systems.

Thread Compatibility Quick Reference

| Thread Type | Angle | Seal Type | Common Use |

|---|---|---|---|

| BSPP | 55° | Washer/Sealant | Low-pressure water |

| BSPT | 55° | Thread Deformation | Gas/Steam |

| NPT | 60° | Tapered | U.S. pipelines |

Tips for BSP Thread Identification

- Use a BSP thread gauge to measure pitch.

- Calipers determine major diameter.

- Check for taper visually or with a fit test.

.

.

FAQ

Conclusion

Mastering BSP thread charts is essential for engineers and technicians. Professionals can ensure durable, leak-free systems across industries by adhering to ISO 228/7 standards, using precise measurement tools, and understanding BSP thread compatibility. Always prioritize accurate BSP thread identification and consult the pipe Schedule Chart alongside other reference materials for optimal results.

Way cool! Some very valid points! I appreciate you penning this write-up

and also the rest of the website is also very good.

Thank you a bunch for sharing this with all folks you really realize what

you’re speaking approximately! Bookmarked. Please also

consult with my site =). We can have a link exchange agreement between us

yes please share your email and website

I saw a lot of website but I think this one contains something extra in it in it

Hi! This post could not be written any better! Reading this post reminds me of my good old room mate! He always kept talking about this. I will forward this post to him. Pretty sure he will have a good read. Thanks for sharing!